XT LASER US INC

Laser Cutting Machine

Your American Industrial Partner

Search productSearch post

Laser Cutting Machine

Your American Industrial Partner

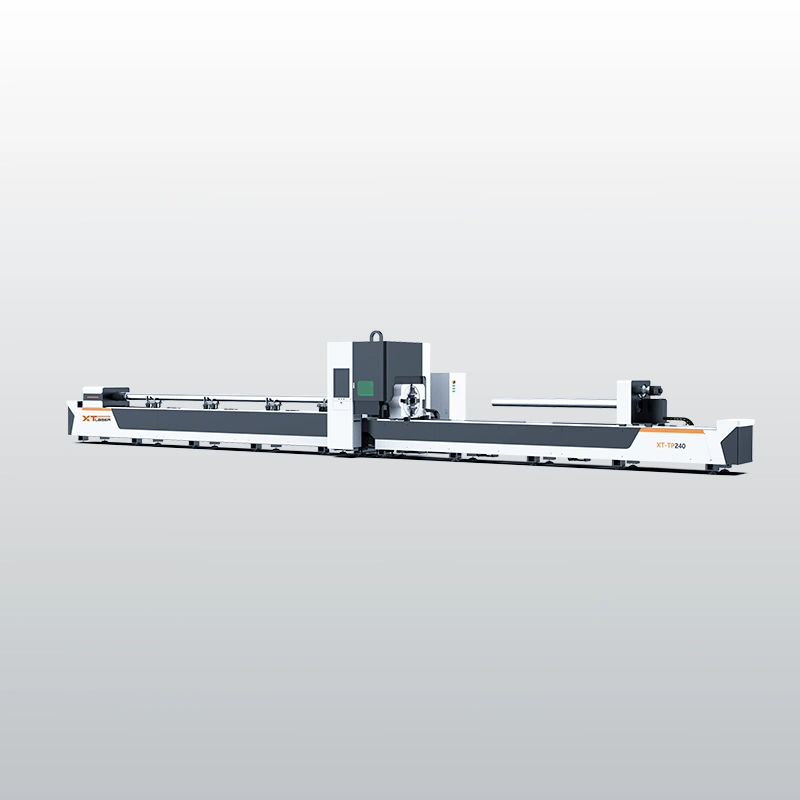

Categories: laser cutting, Sheet metal Laser Cutting Machine

3000W–12000W

3000W–12000W

Enables high‑efficiency processing of 1‑25 mm stainless steel/carbon steel. Precise energy control ensures stable cutting, smoother edges, and consistent high‑quality output.

Enables high‑efficiency processing of 1‑25 mm stainless steel/carbon steel. Precise energy control ensures stable cutting, smoother edges, and consistent high‑quality output.

Utilizes low‑weld splicing technology with a scientific structural layout. Corner welding reinforcement enhances overall stability, while balanced configuration ensures even force distribution on both sides, providing a solid guarantee for long‑term, high‑precision machining.

Utilizes low‑weld splicing technology with a scientific structural layout. Corner welding reinforcement enhances overall stability, while balanced configuration ensures even force distribution on both sides, providing a solid guarantee for long‑term, high‑precision machining.

The fully enclosed housing design meets European safety standards for safety and environmental protection,

prevents spark splash, isolates laser radiation, and minimizes smoke and dust dispersion.

The fully enclosed housing design meets European safety standards for safety and environmental protection, prevents spark splash, isolates laser radiation, and minimizes smoke and dust dispersion.

Internally arranged with a rational layout, the machine occupies a footprint of under 20 m² (215 ft²) when fully deployed. Its small footprint allows for flexible placement, saving valuable factory floor space.

Internally arranged with a rational layout, the machine occupies a footprint of under 20 m² (215 ft²) when fully deployed. Its small footprint allows for flexible placement, saving valuable factory floor space.

Features zoned control with centralized dust collection, reducing smoke and dust pollution, lowering equipment failure rates, ensuring safety, and enabling efficient processing.

Features zoned control with centralized dust collection, reducing smoke and dust pollution, lowering equipment failure rates, ensuring safety, and enabling efficient processing.

One‑touch automatic door opening and lifting functions eliminate manual operation, enhancing safety and processing efficiency.

One‑touch automatic door opening and lifting functions eliminate manual operation, enhancing safety and processing efficiency.

Loading is effortless—the table extends fully, eliminating bending or forcing materials into place. Unloading is convenient, with the entire work surface within easy reach.

Loading is effortless—the table extends fully, eliminating bending or forcing materials into place. Unloading is convenient, with the entire work surface within easy reach.

The entire machine is shipped as a single unit, requiring no on‑site assembly. Simply connect power at your facility, and it is ready to cut.

The entire machine is shipped as a single unit, requiring no on‑site assembly. Simply connect power at your facility, and it is ready to cut.

| Parameter&configration List ●standard configuration, ○optional configuration, ×No configuration required |

||||||

| Item | Subitem | XT-AL6060 (Linear Motor) | XT-A6060 (Ball Screw) | XT-A1309 | XT-A1510 | XT-A1530-V2.0 |

| Basic Information | Working Area | 23.62in x 23.62in | 23.62in x 23.62in | 51.18in x 35.43in | 59.06in x 39.37in | 60.24in x 120.08in |

| Table Load Capacity | 110.23 lb | 110.23 lb | 242.51 lb | 308.65 lb | 1984.16 lb (0.98in max plate thickness) | |

| Machine Dimensions | 85.83in x 63.39in x 78.74in | 76.77in x 57.09in x 78.74in | 95.28in x 87.80in x 87.80in | 124.80in x 79.13in x 86.61in | 183.03in x 88.98in x 76.77in (183.03in x 157.48in x 76.77in) | |

| Machine Weight (varies with power) | 3968.32 lb | 3527.40 lb | 4409.25 lb | 6393.41 lb | 7936.64 lb | |

| Maximum Interpolation Speed | 262.47 ft/min | 196.85 ft/min | 295.28 ft/min | 360.89 ft/min | 393.70 ft/min | |

| Maximum Interpolation Acceleration | 1.0G | 1.0G | 1G | 1G | 0.8G | |

| Positioning Accuracy | ±1.20 × 10⁻⁴ in/ft | ±3.60 × 10⁻⁴ in/ft | ±3.60 × 10⁻⁴ in/ft | ±3.60 × 10⁻⁴ in/ft | ±3.60 × 10⁻⁴ in/ft | |

| Repeatability | ±0.00016in | ±0.0012 in | ±0.0012 in | ±0.0012 in | ±0.0012 in | |

| Total Power | Total Power/Current (with 12KW laser) | X | X | X | X | 55KW/110A |

| Total Power/Current (with 6KW laser) | X | X | X | 30KW/60A | 30KW/60A | |

| Total Power/Current (with 3KW laser) | 15KW/36A | 15KW/36A | 15KW/36A | 20KW/40A | 20KW/40A | |

| Total Power/Current (with 2KW laser) | 12KW/44A | 12KW/44A | 12KW/44A | 17KW/44A | 17KW/44A | |

| Total Power/Current (with 1.5KW laser) | 10KW/36A | 9KW/35A | 9KW/35A | 10KW/39A | 10KW/39A | |

| Cutting Accuracy (1mm stainless steel) | φ1.18in Circle Roundness | ≤0.004in | ≤0.004in | ≤0.004in | ≤0.004in | ≤0.004in |

| □1.18in Adjacent Side Dimension Difference | ≤0.002in | ≤0.002in | ≤0.002in | ≤0.002in | ≤0.002in | |

| □7.48in Adjacent Side Dimension Difference | ≤0.002in | ≤0.002in | ≤0.002in | ≤0.002in | ≤0.002in | |

| □7.48in Diagonal Dimension Difference | ≤0.004in | ≤0.004in | ≤0.004in | ≤0.004in | ≤0.004in | |

| Mechanical Configuration | Bed Construction | Pipe Welded Bed | Pipe Welded Bed | Pipe Welded Bed | Plate Welded Bed | Plate Welded Bed |

| Beam Structure | Aluminum Profile Module | Aluminum Profile Module | Aluminum Profile Beam | Aluminum Profile Beam | Aluminum Profile Beam | |

| Guide Rails | ● | ● | XT Laser Guide Rails | XT Laser Guide Rails | XT Laser Guide Rails | |

| Rack | X | X | XT Laser Rack | XT Laser Rack | XT Laser Rack | |

| Servo Motor & Driver | Linear Motor (Peak<3.5kw) | VEICHI Servo Bus (X:750W Y:750W Z:0.3KW) | VEICHI Servo Bus (X:750W Y:750W Z:0.4KW) | VEICHI Servo Bus(X:1KW Y:1.5KW Z:0.4KW) | VEICHI Servo Bus(X:1KW Y:1.5KW Z:0.4KW) | |

| Reducer | X | X | XT Laser Reducer | XT Laser Reducer | XT Laser Reducer | |

| Automatic Lubrication Function | ● | ● | ● | ● | ● | |

| Blade Thickness | 0.12in | 0.31in Aluminum | 0.12in | 0.12in(≤6000W) | 0.12in(≤6000W); 0.20in(>6000W) | |

| Bed/Carriage Fire Brick | X | X | X | ○Optional <6000W | ○Optional <6000W | |

| ●Standard ≥6000W | ●Standard ≥6000W | |||||

| Pull-out Operation Table | X | X | X | ●(Electric) | ●(Electric) | |

| Marble Table | ● | ● | X | X | X | |

| Zone Dust Removal | X | X | X | X | ● | |

| Enclosed Full Enclosure | ● | ● | ● | ● | ● | |

| Electrical Configuration | Main Electrical Components | X | X | ●Domestic CHINT/ | ●Domestic CHINT/ | ●Domestic CHINT/ |

| Foreign Siemens | Foreign Siemens | Foreign Siemens | ||||

| Control System + Cutting Head | ●<6KW 2000E+B3 Series | ●<6KW 2000E+B3 Series | ●<6KW 2000E+B3 Series | ●<6KW 2000E+B3 Series | ●<6KW 2000E+B3 Series | |

| X | X | X | ●6KW 4000E+B4 Series | ●6-12KW 4000E+B4 Series | ||

| X | X | X | X | ○12KW 8000+B6 Series (Includes professional nesting, excludes Tianyan) | ||

| Nesting Software | ●Network Nesting | ●Network Nesting | ●Network Nesting | ●Network Nesting | ●Network Nesting | |

| Proportional Valve | ●≤6000W Foreign Aventics/Domestic Xingyu | ●≤6000W Foreign Aventics/Domestic Xingyu | ●≤6000W Foreign Aventics/Domestic Xingyu | ●≤6000W Foreign Aventics/Domestic Xingyu | ●≤6000W Foreign Aventics/Domestic Xingyu, | |

| ●>6000W Aventics | ||||||

| Display Size | 18.5in | 18.5in | 21.5in | 24in | 27in | |

| Smart Configuration | Laser Cutting Process Database | ● | ● | ● | ● | ● |

| Auxiliary Gas Low Pressure Alarm | ●≤6000W (System Setting) | ●≤6000W (System Setting) | ●≤6000W (System Setting) | ●≤6000W (System Setting) | ●≤6000W (System Setting) | |

| ●>6000W Additional External | ||||||

| Nitrogen Proportional Valve | ○ | ○ | ○ | ○ | ○≤6KW Optional | |

| ●≥12KW Standard | ||||||

| Side Blowing Cooling | ○Optional <6000W | ○Optional <6000W | ○Optional <6000W | ○Optional <6000W | ○Optional <6000W | |

| ●Standard ≥6000W | ●Standard ≥6000W | ●Standard ≥6000W | ●Standard ≥6000W | ●Standard ≥6000W | ||

| Auxiliary Configuration | XT Laser Water Chiller | XT Laser Water Chiller (Not Specifiable) | XT Laser Water Chiller (Not Specifiable) | XT Laser Water Chiller (Not Specifiable) | XT Laser Water Chiller (Not Specifiable) | XT Laser Water Chiller (Not Specifiable) |

| Dust Removal Equipment | ●One Centrifugal Fan 1.5kw | ●One Centrifugal Fan1.5kw | ●One Centrifugal Fan 1.5kw | ●One Centrifugal Fan1.5kw | ●One Centrifugal Fan5.5kw | |

| Optional Configuration | XT Laser Dust Collector (No Fan by Default) | ○XT Laser Dust Collector (See Auxiliary Selection Table) | ○XT Laser Dust Collector (See Auxiliary Selection Table) | ○XT Laser Dust Collector (See Auxiliary Selection Table) | ○XT Laser Dust Collector (See Auxiliary Selection Table) | ○XT Laser Dust Collector (See Auxiliary Selection Table) |

| WIFI Function | ○ | ○ | ○ | ○ | ○ | |

| XT Laser Air Compressor | ○XT Laser Air Compressor (See Auxiliary Selection Table) | ○XT Laser Air Compressor (See Auxiliary Selection Table) | ○XT Laser Air Compressor (See Auxiliary Selection Table) | ○XT Laser Air Compressor (See Auxiliary Selection Table) | ○XT Laser Air Compressor (See Auxiliary Selection Table) | |

| XT Laser Voltage Stabilizer | ○XT Laser Voltage Stabilizer (See Auxiliary Selection Table) | ○XT Laser Voltage Stabilizer (See Auxiliary Selection Table) | ○XT Laser Voltage Stabilizer (See Auxiliary Selection Table) | ○XT Laser Voltage Stabilizer (See Auxiliary Selection Table) | ○XT Laser Voltage Stabilizer (See Auxiliary Selection Table) | |

| Electrical Cabinet (with Air Conditioner) | ○ | ○ | ○ | ○ | ○ | |

| Protective Goggles | ●(Overseas) | ●(Overseas) | ●(Overseas) | ●(Overseas) | ●(Overseas) | |

| ○(Domestic) | ○(Domestic) | ○(Domestic) | ○(Domestic) | ○(Domestic) | ||

Technical Mastery

At its core lies a German-engineered LED module with TLCI 97 (Television Lighting Consistency Index), making it a favorite for high-end photography studios and boutique hotels requiring true color rendering. The self-cooling aluminum heat sink maintains optimal temperatures even during 24/7 operation, while the DALI-2 dimming protocol ensures seamless integration with building automation systems.

Sustainable Luxury

Certified Cradle to Cradle Silver, the glass contains 30% recycled content, and the driver complies with EU Ecodesign 2025 energy standards. A hidden service hatch allows easy maintenance without dismantling the entire fixture.

Certified Cradle to Cradle Silver, the glass contains 30% recycled content, and the driver complies with EU Ecodesign 2025 energy standards. A hidden service hatch allows easy maintenance without dismantling the entire fixture.

We use cookies to optimize our website , analyze traffic, and provide you with more relevant service information. Some cookies may be set by third-party service providers and may store or access information on your device, such as unique identifiers or browsing behavior. Some of these cookies are strictly necessary for the site's basic functions.

Our privacy policy

And we will contact you within 24 hours