XT LASER US INC

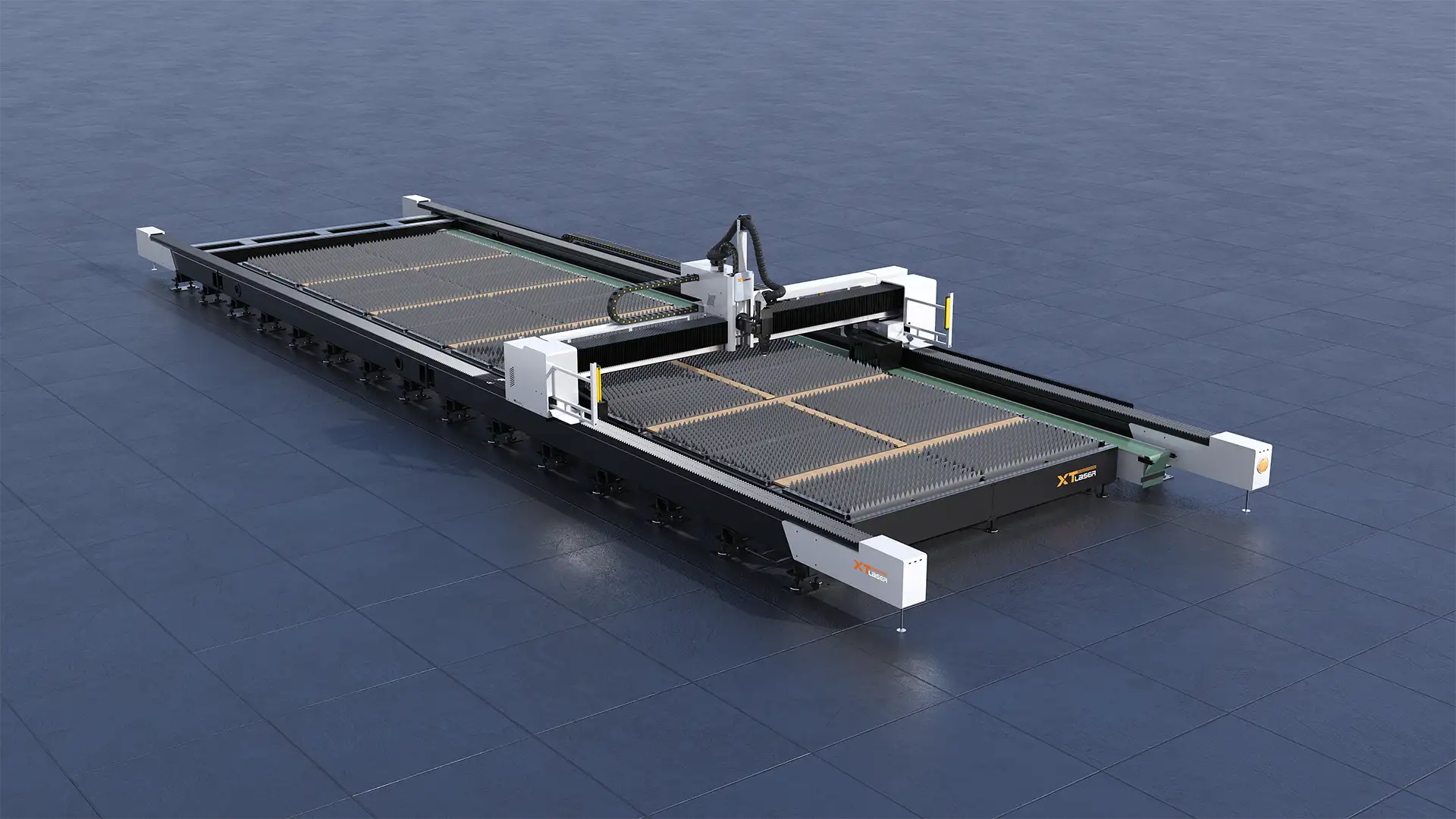

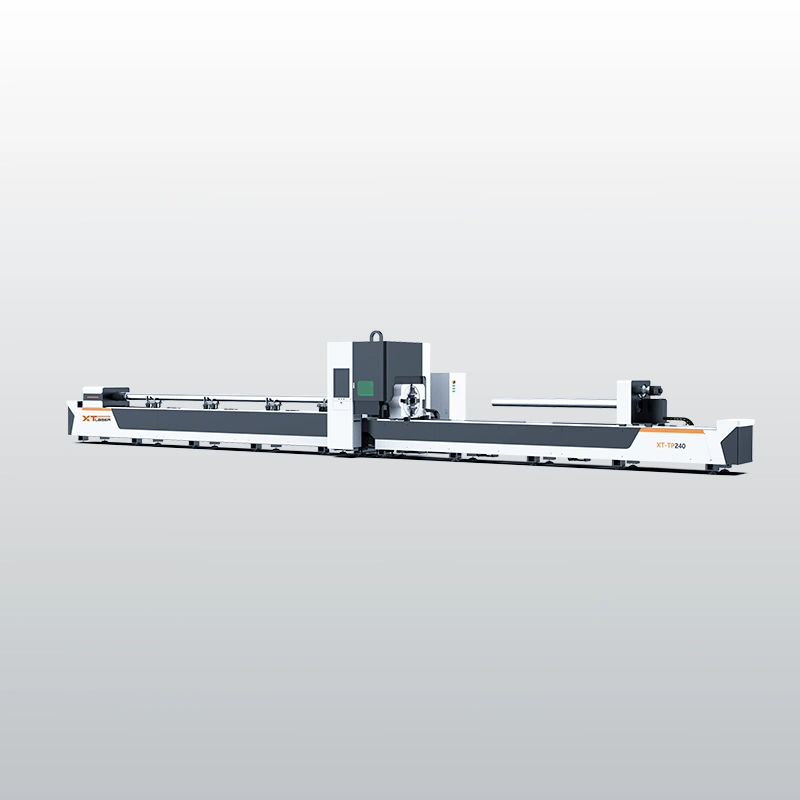

Laser Cutting Machine

Your American Industrial Partner

Search productSearch post

Laser Cutting Machine

Your American Industrial Partner

Categories: laser cutting, Sheet metal Laser Cutting Machine, Ultra High Power Laser Cutting Machine

It integrates both laser and flame functions to

achieve efficient cutting of ultra-thick plates up to 200 mm thick.

It integrates both laser and flame functions to achieve efficient cutting of ultra-thick plates up to 200 mm thick.

The combined advantages of laser focused energy rapid piercing and flame coarse

spot rapid slag removal increase cutting efficiency by 30%.

The combined advantages of laser focused energy rapid piercing and flame coarse

spot rapid slag removal increase cutting efficiency by 30%.

The cutting edges have better perpendicularity and a smoother surface,

reducing the need for secondary processing steps such as grinding, lowering processing costs, and increasing product yield

The cutting edges have better perpendicularity and a smoother surface,

reducing the need for secondary processing steps such as grinding, lowering processing costs, and increasing product yield

It supports both pure laser and laser-flame hybrid modes, and switching from hybrid mode to pure laser mode takes only 60 seconds.

enabling agile conversion between thin/medium-thick plate and thick plate processing tasks, adapting to different production scenarios.

It supports both pure laser and laser-flame hybrid modes, and switching from hybrid mode to pure laser mode takes only 60 seconds.

enabling agile conversion between thin/medium-thick plate and thick plate processing tasks, adapting to different production scenarios.

The system provides real-time monitoring of the pressure in three gas supply lines: natural gas, auxiliary gas,and cutting gas, with immediate alarms in case of abnormalities. This ensures a stable gas supply,avoids cutting defects and safety hazards, and improves the reliability of the processing.

The system provides real-time monitoring of the pressure in three gas supply lines: natural gas, auxiliary gas,and cutting gas, with immediate alarms in case of abnormalities. This ensures a stable gas supply,avoids cutting defects and safety hazards, and improves the reliability of the processing.

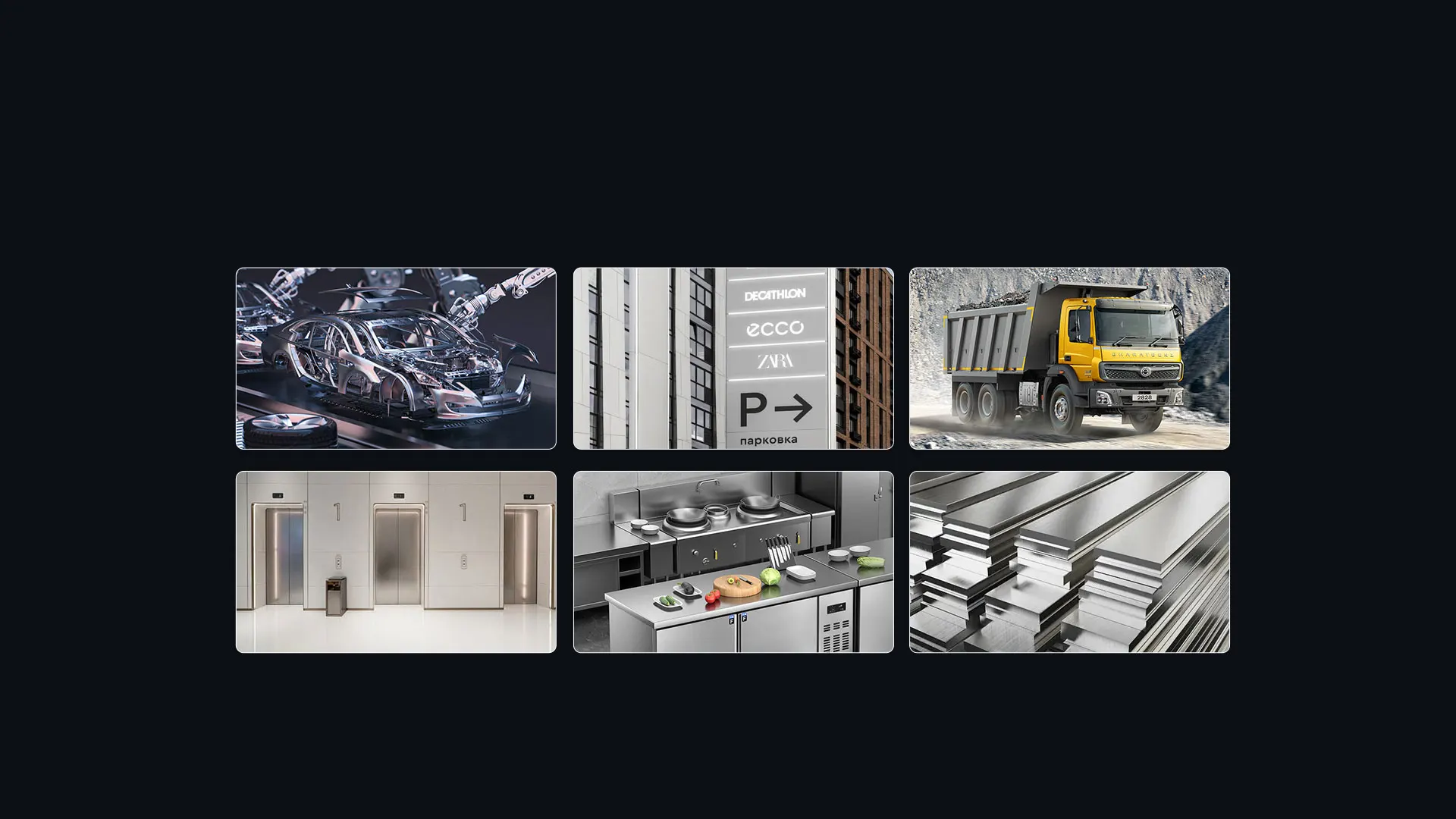

Widely used in steel structure workshops, municipal pipelines, urban constructionconstruction machinery

and other industries

| Latest Equipment Parameter & Configuration List ● Standard Configuration, ○ Optional Configuration, × No Configuration Required |

||||

| Project | Sub-item | XT-L32120A | XT-L32160A | XT-L32240A |

| Basic Information | Straight Cutting Format (in) | 127.5" × 484.2" | 127.5" × 641.7" | 127.5" × 944.8" |

| Bevel Cutting Format (±50°) | 70.8" × 484.2" | 70.8" × 641.7" | 70.8" × 944.8" | |

| Equipment Weight (Approx.) | 11,684 lbs | 13,668 lbs | 17,416 lbs | |

| Max. Linkage Speed | 1,968 in/min (50m/min) | |||

| Max. Acceleration | 0.5G | |||

| Positioning Accuracy | ±0.002 in/ft | |||

| Repeat Positioning Accuracy | ±0.002 in | |||

| Total Power/Current (with 20KW Laser) | 92KW / 184A | |||

| Cutting Accuracy (0.04" Stainless) |

Roundness of φ1.18" Circle | ±0.004 in | ||

| □1.18" Side Dimension Error | ±0.002 in | |||

| □7.48" Side Dimension Error | ±0.002 in | |||

| □7.48" Diagonal Dimension Error | ±0.004 in | |||

| Mechanical Configuration | Gantry Structure | Steel Gantry | ||

| Guide Rail | XT Precision Rail | |||

| Gear Rack | XT Precision Rack | |||

| Servo Motor & Driver | VEICHI Bus-type High-speed Servo | |||

| Reducer | XT Reducer | |||

| Automatic Lubrication Function | ● | |||

| Worktable | Pure Laser | ○≤20kW (0.2" slats) ○≥30kW (0.3" slats) |

||

| Composite Cutting | ○ (0.4" slats) | |||

| Material Collection Cart | ○ | |||

| Independent Electric Cabinet/Gas Box | ● | |||

| Independent Control Console | ● | |||

| Electrical Configuration | Main Electrical Components | ● CHINT (Domestic) / SIEMENS (Overseas) | ||

| Control System + Cutting Head | ● Bevel ≤20kW: FSCUT9100 + BLTFX0 Series + AB Axis | |||

| ● Flat ≤20kW: WX-9000 + NC153 Series | ||||

| Nesting Software | ● Networked Nesting | |||

| Proportional Valve | Laser | ● >6000W Aventics | ||

| Composite Cutting | ● | |||

| Monitor Size | 21.5" | |||

| Intelligent Configuration | Laser Cutting Process Database | ● | ||

| Low Gas Pressure Alarm | ● | |||

| Nitrogen Proportional Valve | ○ ≤6kW Optional / ● ≥12kW Standard | |||

| Side-blow Cooling | ● | |||

| Safety Light Curtain | ● | |||

| Auxiliary & Options | XT Water Chiller | XT Brand (Factory Specified) | ||

| Option Items | XT Dust Collector / Fan | ○ Optional based on requirements | ||

| WIFI Function | ○ | |||

| Air Compressor / Stabilizer | ○ Optional XT Brand | |||

| Foundation Plates & Bolts | ○ | |||

We use cookies to optimize our website , analyze traffic, and provide you with more relevant service information. Some cookies may be set by third-party service providers and may store or access information on your device, such as unique identifiers or browsing behavior. Some of these cookies are strictly necessary for the site's basic functions.

Our privacy policy

And we will contact you within 24 hours