XT LASER US INC

Laser Cutting Machine

Your American Industrial Partner

Search productSearch post

Laser Cutting Machine

Your American Industrial Partner

Categories: laser cutting, Sheet metal Laser Cutting Machine, Ultra High Power Laser Cutting Machine

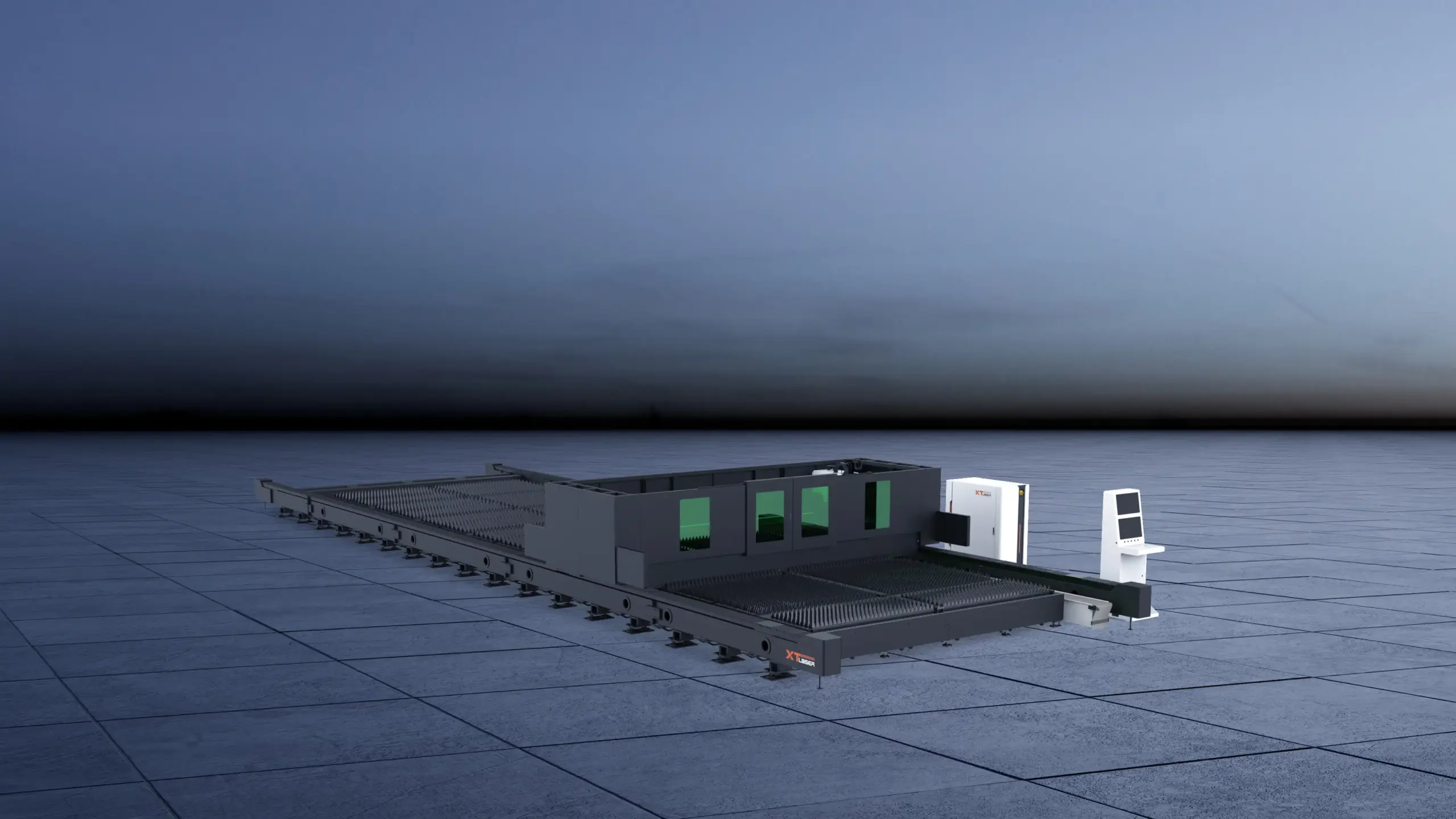

Ultra-large format thick cutting

12000W-120000W

Ultra-large format thick cutting |12000W-120000W

Ultra-large format and flexible customization,

equipped withhigh power,supports one-time loading and cutting of wholeboards, thick boards and multiple boards

Ultra-large format and flexible customization,equipped withhigh power,supports one-time loading and cutting of wholeboards, thick boards and multiple boards

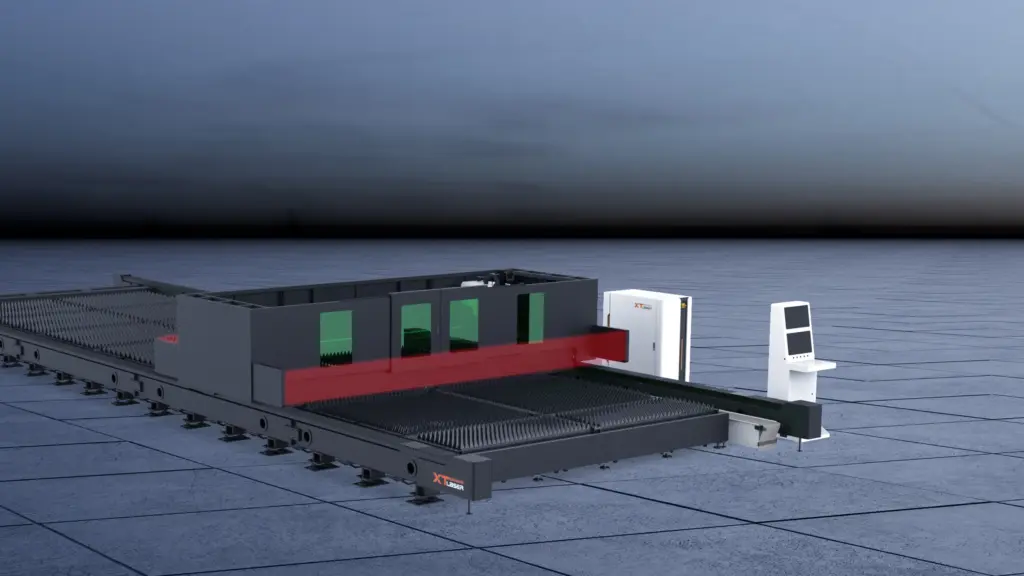

The precision beam suspension structure designhas adaptive adjust mentfunction

to maintainthe cutting head movement accuracy

The precision beam suspension structure designhas adaptive adjust mentfunction

to maintainthe cutting head movement accuracy

The segmented modular bed allows for customized cutting lengths based onfactory layout and order type,

while also facilitating convenient delivery and reducing the burden on customers.

The segmented modular bed allows for customized cutting lengths based onfactory layout and order type,

while also facilitating convenient delivery and reducing the burden on customers.

Supports perforation of ultra-thick platesand effcient penetration

Supports perforation of ultra-thick platesand effcient penetration

Intelligently detect the warping of the plate to avoid laserhead collision and reduce maintenance costs

Widely used in steel structure workshops, municipal pipelines, urban constructionconstruction machinery

and other industries

| Parameter&configration List ●standard configuration, ○optional configuration, ×No configuration required |

||||

| Item | Sub-item | XT-L32120 | XT-L32160 | XT-L32240 |

| Basic Information | Processing Area | 127.95x484.25 in | 127.95x641.73 in | 127.95x944.88 in |

| Machine Weight (varies with power) | 9479.88 lb | 11684.50 lb | 14330.05 lb | |

| Max. Interpolation Speed | 1968.50 in/min | |||

| Max. Acceleration | 0.5G | |||

| Positioning Accuracy | ±6 × 10⁻⁴ in/ft | |||

| Repeat Positioning Accuracy | ±0.0020 in | |||

| Machine Power | Total Power / Current (with 60KW Laser) | 259KW/518A | ||

| Total Power / Current (with 40KW Laser) | 175KW/350A | |||

| Total Power / Current (with 30KW Laser) | 133KW/266A | |||

| Total Power / Current (with 20KW Laser) | 92KW/184A | |||

| Total Power / Current (with 12KW Laser) | 58KW/116A | |||

| Cutting Accuracy Parameters(0.03937 in Stainless Steel) | Roundness of φ1.181 in circle | ±0.0039 in | ||

| Adjacent Side Dimension Difference of □1.181 in | ±0.0020 in | |||

| Adjacent Side Dimension Difference of □7.4803 in | ±0.0020 in | |||

| Diagonal Dimension Difference of □7.4803 in | ±0.0039 in | |||

| Mechanical Configuration | Bed Structure | Butted Pipe Welded Bed | ||

| Beam Structure | Steel Beam | |||

| Guide Rail | XT Laser Guide Rail | |||

| Rack | XT Laser Rack | |||

| Servo Motor & Driver | VEICHI Bus High-Speed Servo Motor | |||

| (X:1.5KW Y:2.9KW Z:0.75KW) | ||||

| Reducer | XT Laser Reducer | |||

| Automatic Lubrication Function | ● | |||

| Table Frame | ○≤20000W (0.197 in Knife Strip) | |||

| ○≥30000W (0.315 in Knife Strip) | ||||

| Material Receiving Cart | ○ | |||

| Independent Control Cabinet, Air Box | ● | |||

| Independent Console | ● | |||

| Electrical Configuration | Main Electrical Configuration | ● Domestic Chint/ | ||

| Overseas Siemens | ||||

| Control System + Cutting Head | ●12-20KW 6000+B4 Series | |||

| ●≥30KW 8000+B6 Series (Including professional nesting, including Tianyan) | ||||

| ○12-20KW 8000+B6 Series (Including professional nesting, including Tianyan) | ||||

| Nesting Software | ● Online Nesting | |||

| Proportional Valve | ●>6000W Aventics | |||

| Display Size | 21.5 | |||

| Intelligent Configuration | Laser Cutting Process Database | ● | ||

| Auxiliary Gas Low Pressure Alarm Function | ● | |||

| Nitrogen Proportional Valve | ○≤6KW Optional | |||

| ●≥12KW Standard | ||||

| Side Blow Cooling | ● | |||

| Safety Light Curtain | ● | |||

| Auxiliary Configuration | XT Laser Chiller | XT Laser Chiller (Not allowed to specify) | ||

| Optional Configuration | XT Laser Dust Collector (default without fan) | ○ XT Laser Dust Collector (See auxiliary equipment selection table) | ||

| Fan | ○ Optional according to customer requirements | |||

| Following Dust Extraction Cart | ○ Optional according to customer requirements | |||

| WIFI Function | ○ | |||

| XT Laser Air Compressor | ○ XT Laser Air Compressor (See auxiliary equipment selection table) | |||

| XT Laser Voltage Stabilizer | ○ XT Laser Voltage Stabilizer (See auxiliary equipment selection table) | |||

| Safety Goggles | ● (Overseas) | |||

| ○ (Domestic) | ||||

| Base Plate & Expansion Bolts | ○ | |||

Technical Mastery

At its core lies a German-engineered LED module with TLCI 97 (Television Lighting Consistency Index), making it a favorite for high-end photography studios and boutique hotels requiring true color rendering. The self-cooling aluminum heat sink maintains optimal temperatures even during 24/7 operation, while the DALI-2 dimming protocol ensures seamless integration with building automation systems.

Sustainable Luxury

Certified Cradle to Cradle Silver, the glass contains 30% recycled content, and the driver complies with EU Ecodesign 2025 energy standards. A hidden service hatch allows easy maintenance without dismantling the entire fixture.

Certified Cradle to Cradle Silver, the glass contains 30% recycled content, and the driver complies with EU Ecodesign 2025 energy standards. A hidden service hatch allows easy maintenance without dismantling the entire fixture.

We use cookies to optimize our website , analyze traffic, and provide you with more relevant service information. Some cookies may be set by third-party service providers and may store or access information on your device, such as unique identifiers or browsing behavior. Some of these cookies are strictly necessary for the site's basic functions.

Our privacy policy

And we will contact you within 24 hours